AUTO spin

Pin drilling unit

Advantages

- Time and cost saving due to reduced use of dental plaster.

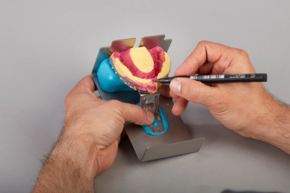

- Safe positioning and alignment in challenging impression situations due to the innovative Renfert Level Controller.

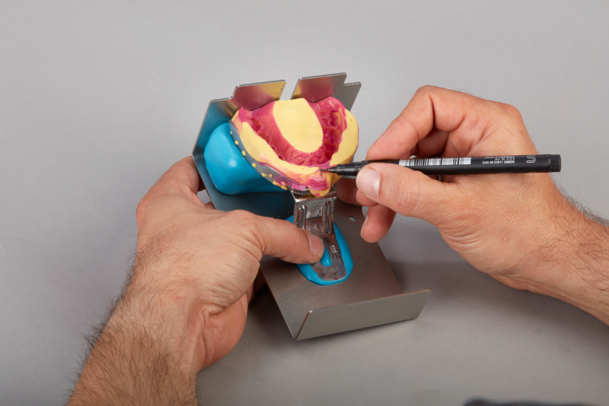

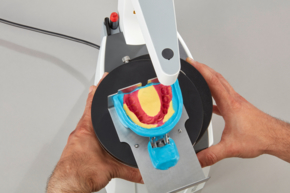

- Flexible use for almost any plate geometry due to the universal plate holder with secure double fixation.

Details

- Optimal friction of the pins due to holes drilled with high precision.

- High working comfort with the automatic drilling process.

AUTO spin, 220-240 V

AUTO spin, drill, plate holder, impression holder, Level Controller, adjusting tool for drilling depth (screwdriver Torx T5), tool for drill fixing (angled key Torx T10), laser sticker set, Quick Start Guide, AUTO spin system illustrated manual

AUTO spin, 120 V

AUTO spin, drill, plate holder, impression holder, Level Controller, adjusting tool for drilling depth (screwdriver Torx T5), tool for drill fixing (angled key Torx T10), laser sticker set, Quick Start Guide, AUTO spin system illustrated manual

| AUTO spin, 220-240 V | AUTO spin, 120 V | |

|---|---|---|

| Item number | 18600000 | 18601000 |

| Permissible mains voltage | 220 - 240 V | 120 V |

| Permissible mains frequency | 50 - 60 Hz | 50 - 60 Hz |

| Weight | 7.6 kg 16.8 lbs |

7.6 kg 16.8 lbs |

| Dimensions (W x H x D) | 180 x 368 x 275 mm 7.1 x 14.5 x 10.8 " |

180 x 368 x 275 mm 7.1 x 14.5 x 10.8 " |

| Power consumption (during drilling) | 115 W | 115 W |

| Sound pressure level (LpA) (in accord. with DIN EN ISO 11202) | 70 dB(A) | 70 dB(A) |

| Laser Class | 2 | 2 |

| Permissible drill shaft diameter Ø | 3 - 0.006 mm | 3 - 0.006 mm |

| Permissible drill length | 38 - 40 mm 1.5 - 1.57 " |

38 - 40 mm 1.5 - 1.57 " |

| Laser Wavelength | 630 - 680 nm | 630 - 680 nm |

| Output power P0 | 1 mW | 1 mW |

| Model base | Plastic | Plastic |

| Compatibility | for ex. Zeiser® system | for ex. Zeiser® system |

- Item number

- 18600000

- Permissible mains voltage

- 220 - 240 V

- Permissible mains frequency

- 50 - 60 Hz

- Weight

-

7.6 kg

16.8 lbs - Dimensions (W x H x D)

-

180 x 368 x 275 mm

7.1 x 14.5 x 10.8 " - Power consumption (during drilling)

- 115 W

- Sound pressure level (LpA) (in accord. with DIN EN ISO 11202)

- 70 dB(A)

- Laser Class

- 2

- Permissible drill shaft diameter Ø

- 3 - 0.006 mm

- Permissible drill length

-

38 - 40 mm

1.5 - 1.57 " - Laser Wavelength

- 630 - 680 nm

- Output power P0

- 1 mW

- Model base

- Plastic

- Compatibility

- for ex. Zeiser® system

- Item number

- 18601000

- Permissible mains voltage

- 120 V

- Permissible mains frequency

- 50 - 60 Hz

- Weight

-

7.6 kg

16.8 lbs - Dimensions (W x H x D)

-

180 x 368 x 275 mm

7.1 x 14.5 x 10.8 " - Power consumption (during drilling)

- 115 W

- Sound pressure level (LpA) (in accord. with DIN EN ISO 11202)

- 70 dB(A)

- Laser Class

- 2

- Permissible drill shaft diameter Ø

- 3 - 0.006 mm

- Permissible drill length

-

38 - 40 mm

1.5 - 1.57 " - Laser Wavelength

- 630 - 680 nm

- Output power P0

- 1 mW

- Model base

- Plastic

- Compatibility

- for ex. Zeiser® system

Technical data

| AUTO spin, 220-240 V | AUTO spin, 120 V | |

|---|---|---|

| Item number | 18600000 | 18601000 |

| Permissible mains voltage | 220 - 240 V | 120 V |

| Permissible mains frequency | 50 - 60 Hz | 50 - 60 Hz |

| Weight | 7.6 kg 16.8 lbs |

7.6 kg 16.8 lbs |

| Dimensions (W x H x D) | 180 x 368 x 275 mm 7.1 x 14.5 x 10.8 " |

180 x 368 x 275 mm 7.1 x 14.5 x 10.8 " |

| Power consumption (during drilling) | 115 W | 115 W |

| Sound pressure level (LpA) (in accord. with DIN EN ISO 11202) | 70 dB(A) | 70 dB(A) |

| Laser Class | 2 | 2 |

| Permissible drill shaft diameter Ø | 3 - 0.006 mm | 3 - 0.006 mm |

| Permissible drill length | 38 - 40 mm 1.5 - 1.57 " |

38 - 40 mm 1.5 - 1.57 " |

| Laser Wavelength | 630 - 680 nm | 630 - 680 nm |

| Output power P0 | 1 mW | 1 mW |

| Model base | Plastic | Plastic |

| Compatibility | for ex. Zeiser® system | for ex. Zeiser® system |

- Item number

- 18600000

- Permissible mains voltage

- 220 - 240 V

- Permissible mains frequency

- 50 - 60 Hz

- Weight

-

7.6 kg

16.8 lbs - Dimensions (W x H x D)

-

180 x 368 x 275 mm

7.1 x 14.5 x 10.8 " - Power consumption (during drilling)

- 115 W

- Sound pressure level (LpA) (in accord. with DIN EN ISO 11202)

- 70 dB(A)

- Laser Class

- 2

- Permissible drill shaft diameter Ø

- 3 - 0.006 mm

- Permissible drill length

-

38 - 40 mm

1.5 - 1.57 " - Laser Wavelength

- 630 - 680 nm

- Output power P0

- 1 mW

- Model base

- Plastic

- Compatibility

- for ex. Zeiser® system

- Item number

- 18601000

- Permissible mains voltage

- 120 V

- Permissible mains frequency

- 50 - 60 Hz

- Weight

-

7.6 kg

16.8 lbs - Dimensions (W x H x D)

-

180 x 368 x 275 mm

7.1 x 14.5 x 10.8 " - Power consumption (during drilling)

- 115 W

- Sound pressure level (LpA) (in accord. with DIN EN ISO 11202)

- 70 dB(A)

- Laser Class

- 2

- Permissible drill shaft diameter Ø

- 3 - 0.006 mm

- Permissible drill length

-

38 - 40 mm

1.5 - 1.57 " - Laser Wavelength

- 630 - 680 nm

- Output power P0

- 1 mW

- Model base

- Plastic

- Compatibility

- for ex. Zeiser® system

AUTO spin base plate comfort

Secure fixation and easy pin removal due to stable acrylic base plates with metal disc.

100 pieces

AUTO spin base plate standard

Secure fixation and easy pin removal due to stable acrylic base plates without metal disc.

100 pieces

AUTO spin cone pin drill

Special cutting geometry for smooth inner surfaces and low compressive stress during drilling. Ø: 3 mm (0.12"), Length: 39 mm (1.53")

1 piece

AUTO spin secondary plate

Perfect fit between base and secondary plate.

50 pieces

AUTO spin silicone putty

Silicone putty for fixing, aligning and blocking-out.

1 kg

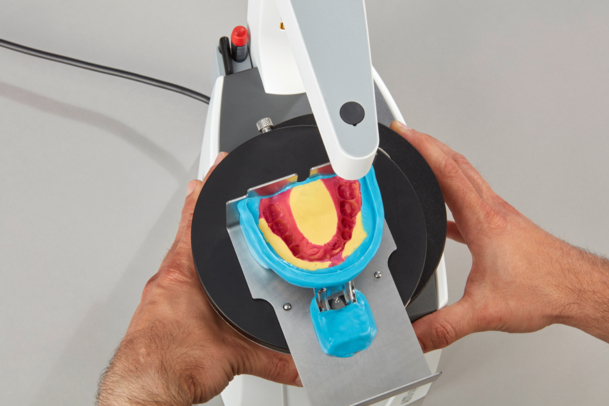

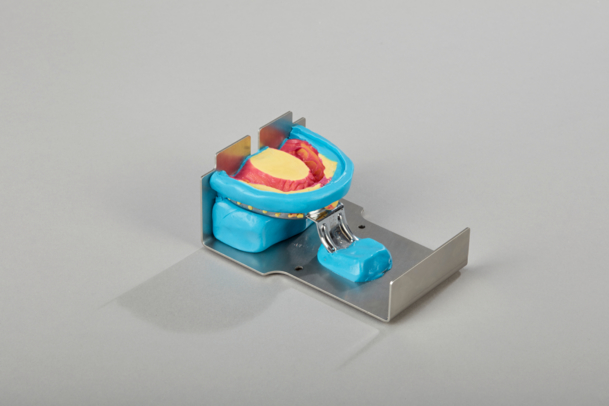

AUTO spin universal impression holder

Dimensionally stable, stainless steel impression holder.

1 piece

AUTO spin universal plate holder

Flexible use of virtually every plate geometry possible with secure dual fixation.

1 piece

AUTO spin cone pin

Cone pin of 14 mm (0.55“) in length for Renfert’s AUTO spin system, Giroform®, Zeiser® or similar systems.

1000 pieces

AUTO spin base plate comfort

Secure fixation and easy pin removal due to stable acrylic base plates with metal disc.

100 pieces

AUTO spin base plate standard

Secure fixation and easy pin removal due to stable acrylic base plates without metal disc.

100 pieces

AUTO spin cone pin drill

Special cutting geometry for smooth inner surfaces and low compressive stress during drilling. Ø: 3 mm (0.12"), Length: 39 mm (1.53")

1 piece

AUTO spin secondary plate

Perfect fit between base and secondary plate.

50 pieces

AUTO spin silicone putty

Silicone putty for fixing, aligning and blocking-out.

1 kg

AUTO spin universal impression holder

Dimensionally stable, stainless steel impression holder.

1 piece

AUTO spin universal plate holder

Flexible use of virtually every plate geometry possible with secure dual fixation.

1 piece

AUTO spin cone pin

Cone pin of 14 mm (0.55“) in length for Renfert’s AUTO spin system, Giroform®, Zeiser® or similar systems.

1000 pieces

AUTO spin, 220-240 VItem number 18600000 |

View spare parts list |

AUTO spin, 120 VItem number 18601000 |

View spare parts list |

-

Repair manual

AUTO spin 1860x000PDF (20.86MB)Multilingual -

Declaration of conformity

AUTO spin 1860x000PDF (978KB)Multilingual -

Declaration of conformity

UKCA AUTO spin / Top spinPDF (318KB) -

Instruction manual

AUTO spin 1860x000PDF (5.44MB)Multilingual -

Quick Start Guide

AUTO spin 1860x000PDF (2.62MB)Multilingual -

Quick Start Guide

AUTO spin 1860x000PDF (3.76MB)Multilingual -

Manual / User guide

Manual / User guide

Manual / User guide

Manual / User guide

Manual / User guide

Manual / User guide

Manual / User guide

Manual / User guide

Manual / User guide

Master models | Manual | DEMaster models | Manual | ENMASTER_MODELS_MANUAL_ZH.PDFMASTER_MODELS_MANUAL_JA.PDFMaster models | Manual | FRMaster models | Manual | ITMaster models | Manual | ESMaster models | Manual | RUMaster models | Manual | PTPDF (4.17MB)PDF (4.56MB)PDF (13.05MB)PDF (4.97MB)PDF (2.06MB)PDF (1.92MB)PDF (1.94MB)PDF (2.12MB)PDF (1.93MB) -

Manual / User guide

AUTO spin 1860x000 | Product use | ENPDF (1.91MB) -

Brochures

Brochures

Brochures

Brochures

Brochures

Brochures

Brochures

Brochures

AUTO spin 1860x000 | Flyer | DEAUTO spin 1860x000 | Flyer | ENPRODUKTFLYER_AUTOSPIN_ZH.PDFAUTO spin 1860x000 | Prospectus | FRAUTO spin 1860x000 | Aviatrice| ITAUTO spin 1860x000 | Volantes | ESAUTO spin 1860x000 | листовка | RUAUTO spin 1860x000 | Folheto | PTPDF (575KB)PDF (573KB)PDF (3.61MB)PDF (575KB)PDF (574KB)PDF (574KB)PDF (577KB)PDF (576KB) -

Catalogue

RENFERT_CATALOG_EN.PDFPDF (29.53MB)

{- title -}

Customer reviews

“The model system has established itself in the education of master dental technicians. Stability, fit and the easy and quick production of models in the course make the system an important component in the practice documents of our master students.”

“Renfert AUTO spin models are the best business card for any laboratory! The functionality, precision and cost-effectiveness of AUTOspin is faultless! Altogether a modern laboratory must have ..”

Guido Bader

Vlatko Krsteski

Show external content

To display this content, you must explicitly agree to the loading of „External content“.

-

View on map

2C Med Coop. Centrale Medico Dentaire

230, Av. du Prof. J.-L. Viala, 34090

MONTPELLIER, France -

View on map

3DBioCAD Taiwan Inc.

5F-1, No. 164, Dun Hua S. Rd., 2-Sec.,

TAIPEI, -

View on map

3S Medikal Tic Ltd.STI.

Tuna Mahallesi 5500/2 Sk. No. 2-6A, 35090

BORNOVA / IZMIR, Türkiye - View on map

-

View on map

ABC Dental AG Dental-Depot

Postfach, 8010

ZÜRICH, Switzerland -

View on map

ABM Dentaire EURL

27 Domaine l'Albarede, 31650

AUZIELLE, France -

View on map

ARSEUS LAB SAS

Valgora Bat C parc Tertiaire, 83160

LA VALETTE DU VAR, France -

View on map

ART Press LLC

Prospect Mira 73/1, 720044

BISHKEK, Kyrgyzstan -

View on map

ASO INTERNATIONAL MANILA, INC.

Atlantica Bldg. 5, Block 12, Phase 1, South Avenue, Cavite Economic Zone,, 4106

Rosario, Cavite,, Philippines -

View on map

AUVERLOR

21, AVENUE DES NOBLES, 31140

LAUNAGUET, France -

View on map

Aarts Techniek & Service

Mattenbies 52, 2957 RJ

NIEUW LEKKERLAND, Netherlands -

View on map

Abodent GmbH Dental-Depot

Alte Straße 95, 27432

Bremervörde, Germany - View on map

-

View on map

Adolf Garlichs GmbH & Co. KG Oldenburger Dental-Depot

Müllersweg 4, 26135

Oldenburg, Germany -

View on map

Agkem Impex Pvt. Ltd.

503-504, 5th floor, Rishabh Corporate Tower, Plot no. 16, Community Center, Karkardooma,, 110092

Delhi, India -

View on map

Al Farsi National Enterprises L.L.C

Flat No: 4, Wy No: 3521, Building No: 1992, Block No: 235, Post Box: 158, Al Khuwair Street, Al Khuwair, 133

MUSCAT, OmanT: +96824485625 -

View on map

Al Sultan United Medical Company W.L.L.

Ghazaly Road, Shuwaikh Free Trade Zone, Khitan Block 7, 13103

SAFAT, Kuwait -

View on map

Alata ltd.

Shota Rustaveli str. 44/42, 720044

BISHKEK, Kyrgyzstan -

View on map

Alberti S.r.l. Forniture Dentali

Via Orzinuovi, 12 G/H, 25125

BRESCIA, Italy -

View on map

Ali Bin Ali Medical w.l.l.

ABA Tower, Airport Road, P.O. Box 75,

DOHA, Qatar -

View on map

Alira Dental Labs

Mazengo Street, 19813

Dar es Salaam, Tanzania, United Republic of -

View on map

Alphabond Dental

Unit 40/28 Barcoo Street, 2069

Roseville NSW, Australia - View on map

-

View on map

Altmann Dental GmbH & Co. KG Dental Depot

Thorackerstraße 16, 96052

Bamberg, Germany -

View on map

American Dent All

6733 San Fernando Rd. , 91201

GLANDALE, CA, United States of America -

View on map

Americana Dental, Inc.

6015 Benjamin Rd Suite # 310, 33634

TAMPA, FL, United States of America -

View on map

Amertsmann GmbH Depot Passau

Alte Poststraße 40, 94036

Passau, Germany -

View on map

Anton Gerl GmbH

Deliusstr. 16, 24114

Kiel, Germany -

View on map

Anton Gerl GmbH

Südwestpark 65, 90449

Nürnberg, Germany - View on map

- View on map

-

View on map

Anton Gerl GmbH

Preußenstraße 19, 66111

Saarbrücken, Germany - View on map

-

View on map

Anton Gerl GmbH

Am Borsigturm 62, 13507

Berlin, Germany -

View on map

Anton Gerl GmbH

Rohrstr. 15, 58093

Hagen, Germany -

View on map

Anton Gerl GmbH

Industriestraße 131 a, 50996

Köln, Germany - View on map

-

View on map

Anton Gerl GmbH

Devrientstraße 5, 01067

Dresden, Germany -

View on map

Anton Gerl GmbH

Liebknechtstr. 88, 08523

Plauen, Germany -

View on map

Anton Gerl GmbH

Garmischer Str. 35, 81373

München, Germany -

View on map

Anton Gerl GmbH

Podbielskistr. 269, 30655

Hannover, Germany -

View on map

Anton Kern GmbH

Frohsinnstraße 11, 63739

Aschaffenburg, Germany -

View on map

Anton Kern GmbH

Am alten Schlachthof 4, 36037

Fulda, Germany - View on map

-

View on map

Anton Kern GmbH Dental Depot

Unterdürrbacher Straße 200, 97080

Würzburg, Germany -

View on map

Anton Kern GmbH Technischer Kundendienst

Unterdürrbacher Straße 200, 97080

Würzburg, Germany -

View on map

Anton Tremschnig Dental-Agentur

Rottenstraße 33, 9330

ALTHOFEN, Austria -

View on map

Antonio Marchesano

Via Don Minzoni 28, 66034

LANCIANO (CH), Italy -

View on map

Apex SPRL

Avenue du Commerce 38, 1420

BRAINE L'ALLEUD, Belgium -

View on map

Apex on Tech

3894 Chesswood Drive, M3J2W6

NORTH YORK, ON, Canada -

View on map

Apex-Material e Equipamento Médico, Lda.

Rua Aval de Cima, 79, 4200-107

PORTO, Portugal -

View on map

Arseus Lab BV

Leeuweriklaan 6-8, 3704 GR

ZEIST, Netherlands - View on map

-

View on map

Art in Smile Laboratory Ltd.

10 Silverdale Road Tadley, RG26 4JJ

HAMPSHIRE, United Kingdom of Great Britain and Northern Ireland -

View on map

Artident Dental-Produkte

Am Forst 39, 74889

Sinsheim, Germany -

View on map

Asia Dental

Flat No.225, BG1, Paschim Vihar, Delhi, West Delhi,, 110063

New Delhi, India -

View on map

Astidental Di Sabbione S.p.A.

Via del Lavoro, 9, 14100

ASTI, Italy -

View on map

Atlanta Dental

1650 Satellite Blvd, 30097

DULUTH, GA, United States of America -

View on map

B & B Dental-Service GbR

Fiete-Schulze-Str. 12, 06116

Halle, Germany - View on map

-

View on map

BDV Horvath Export-Import

Hermann-Steinhäuser-Str. 6, 63065

Offenbach, Germany -

View on map

BIT Dental, S.L.

C/ Los Vientos, 13 (La Torreta), 03600

ELDA (ALICANTE), Spain -

View on map

BLS Labor- und Gerätetechnik GmbH

Aarstr. 38, 65232

Taunusstein, Germany -

View on map

Balsas División Dental S.A. de C.V.

Tajín 110, Col. Narvarte Del Benito Juárez, 03020

MÉXICO D.F., Mexico - View on map

-

View on map

Bart Enterprises Ltd.

42 A, Main Street, BZN 06

BALZAN, Malta - View on map

-

View on map

Beijing Health Tooth Technology Co. Ltd.

104, 1st Floor, Building NO.2, Courtyard 81 Fucheng Road, Haidian District,, 100037

Beijing, China -

View on map

Benco Dental Supply Co.

295 CenterPoint Boulevard, 18640

PITTSTON, PA, United States of America -

View on map

Besser Dental

Rua Agua Branca, 1193 Sala A - Agua Verde, 89041-700

BLUMENAU, Brazil -

View on map

Bijoutil AG

Binninger Straße 123, 4123

ALLSCHWIL, Switzerland -

View on map

BioZeram Solutions S.L.

C/ Canelones, 25, Local 1, 08917

BADALONA, Spain -

View on map

Biodente

Rua Florianópolis, 251 E , 89.812-120

CHAPECÓ, Brazil -

View on map

Biosummer Dental

8 rue Joliot-Curie, 76650

PETIT COURONNE, France -

View on map

Biosys Technologies

Suit # 2C Merherba Plaza (2nd Floor), 33 Topkhana Road, 1000

DHAKA, BangladeshT: +88029563681 -

View on map

Blind S.r.l.

Piazzale Gerbetto 6, 22100

COMO (CO), Italy -

View on map

Blu Dental Group SRL

Via Laura Mantegazza 59C, 00152

ROMA, Italy -

View on map

Boley GmbH u. Co. KG

Julius-Hölder-Straße 32, 70597

Stuttgart, Germany -

View on map

Bonath Dental e.K.

Obere Bahnhofstr. 24, 90556

Cadolzburg, Germany -

View on map

Bora Dental Albania Shpk

Babe Rexha, Pallati Elyol Edil-Al Nr1,

TIRANA 1001, Albania - View on map

-

View on map

Bourgogne Matériel Dentaire

ZA du champ chassy, 71380

CHATENOY EN BRESSE, France -

View on map

Brocadello Forniture Dentali s.a.s.

Via San Bellino 14, 35020

ALBIGNASEGO (PD), Italy -

View on map

Bruns & Klein GmbH Dentalfachhandel

Im Metternicher Feld 5-7, 56072

Koblenz, Germany -

View on map

Buldent Ltd

17 Racho Petkov Kazandjiata str, 1756

SOFIA, Bulgaria -

View on map

Bullnheimer & Co.

Im Tal 12, 86179

Augsburg, Germany -

View on map

Burzacchi S.R.L. Forniture Dentali

Via Tiburtina, 257, 00162

ROMA, Italy -

View on map

Bürkle Dental GmbH Dental Depot

Friedrich-List-Str. 40, 70771

Leinfelden-Echterdingen, Germany -

View on map

C. Klöss Dental GmbH

Hauptstr. 24, 2482

MÜNCHENDORF, Austria - View on map

-

View on map

CDL Comptoir Dentaire Lorrain SAS

21, rue des Garennes, 57155

MARLY, France -

View on map

CHONGQING KANGMEI YATAI MEDICAL DEVICE CO., LTD.

No. 10-4, Business Building, Xinxia Hotel, No. 33 Yuzhou road, Shiqiaopu District Jiulongopo District,

Chongqing, China -

View on map

CKemmer S.r.l. Unipersonale

Via Piemonte, 12/B, 87030

RENDE (CS), Italy -

View on map

CURADEN AG

Centro 2000, 6595

RIAZZINO, Switzerland - View on map

-

View on map

CURADEN AG

Riedstr. 12, 8953

DIETIKON, Switzerland -

View on map

Cap Dentaire - Service A.D.V.

2 bis /2 ter chemin du loup, Z.I., des petits ponts, 93297

TREMBLAY EN FRANCE, France -

View on map

Carrillo Dental, S.L. - Suministros para Odontología

Villa de Silla, 1, 30890

PUERTO LUMBRERAS/MURCIA, Spain -

View on map

Cenger Scandinavia A/S

Urlevvej 6 B, 8783

HORNSYLD, Denmark - View on map

-

View on map

Central Dental Supply

3420 Pharmacy Avenue Unit#3,

SCARBOROUGH, ONT. M1W 2P7, Canada -

View on map

Cera-Tech AG Hr. Vanik Jinoian

Poststraße 13, 4410

LIESTAL, Switzerland -

View on map

Chairside Lab Solutions

355 Post Ave, Ste 101, , 11590

WESTBURY, NY, United States of America -

View on map

Chardiny Thibaud Reparation de Materiel

Jean Monnet Nord 397 rue de la Farlede, 83500

LA SEYNE SUR MER, France -

View on map

Chendu Huaguang Medical Instrument Co., Ltd.

No. 4 Shunsha Lane Section 3rd, First Round Road, 610081

CHENGDU CITY/SICHUAN PROVINCE, China -

View on map

Chubaras Enterprises Ltd.

11 Adekunle Akala Str. Ajao Estate, 100263

LAGOS, Nigeria -

View on map

Comprox Dental

Av. Presidente Castelo Branco, 425 - Jardim Presidente , 86061-335

Londrina, Brazil - View on map

-

View on map

Contacto Dental Emitec S.A.

Las Heras 1761, 11200

MONTEVIDEO, Uruguay -

View on map

Corporación Dental de El Salvador S.A. de C.V.

19 Av. Sur y Calle Arce Plaza Orleans, Locales LA5, LA6, LA26, LA42,

SAN SALVADOR, El Salvador -

View on map

Corrado Valvason

Viale Piave 46/A, 00030

SAN VITO ROMANO, Italy - View on map

- View on map

-

View on map

D.S.C. Dental-Service-Center GmbH

Zum Natten 12, 32289

Rödinghausen, Germany - View on map

-

View on map

DEBOMED Ges. f. Innovation und Beschaffungsmarketing mbH

Im Nordfeld 13, 29336

Nienhagen, Germany -

View on map

DENTALGARAGE UG & Co. KG

Thorackerstraße 16, 96052

Bamberg, Germany -

View on map

DENTALSTORE SPÓŁKA Z O.O., SPOLKA KOMANDYTOWA

TORFOWA 3B, 70-772

SZCZ, Poland -

View on map

DISTRIBUTION DIRECTE DENTAIRE EURL

716 rue du Géneral de Gaulle, 45220

CHATEAU-RENARD, France - View on map

-

View on map

DLGS24 GmbH

Meyerstraße 17, 14776

Brandenburg an der Havel, Germany -

View on map

DT&SHOP GmbH

Mangelsfeld 11-15, 97708

Bad Bocklet, Germany - View on map

-

View on map

De Mari Gianfranco Forniture Dentali

Via Pedemonte 80, 19021

ARCOLA - LA SPEZIA -, Italy -

View on map

Debar Gold Ltd.

105, Schneider Road Suite#116,

KANATA, ONT. K2K 1Y3, Canada - View on map

-

View on map

Dension Dental GmbH & Co. KG

Berliner Str. 40, 63065

Offenbach, Germany -

View on map

Densu Ceramic Dental

Laboratory # 8, Norris Canal Road,,

COLOMBO-10, Sri Lanka - View on map

-

View on map

Dent-Line of Canada, Inc.

1170 Concesion Road 4 R.R. #1,

LORETTO, ONT. L0G 1L0, Canada -

View on map

Dent-Par S.A.

Avda. San Blás 851 Shopping Rahal - Local 20,

CIUDAD DEL ESTE, Paraguay -

View on map

Dent-Thel Depósito Dental

Caballero, 5-7 - Bajos, 08014

BARCELONA, Spain -

View on map

Denta-Quick

Birkenhain 11, 91094

Langensendelbach, Germany -

View on map

Denta-Rep Peter Nötzli

Lehnisweidstr. 26, 8967

WIDEN, Switzerland - View on map

-

View on map

Dentag Italia Srl

Negrellistraße 4, 39100

BOLZANO, Italy -

View on map

Dental 2000 Full-Serv.-Center GmbH & Co KG

Hohmannstraße 6, 04129

Leipzig, Germany -

View on map

Dental 2000 Full-Serv.-Center GmbH & Co KG

Grietgasse 11, 07743

Jena, Germany -

View on map

Dental 2000 Full-Serv.-Center GmbH & Co KG

Krausestraße 102-104, 22049

Hamburg, Germany -

View on map

Dental 2000 Full-Serv.-Center GmbH & Co KG

Mittelstraße 9, 12529

Schönefeld, Germany -

View on map

Dental 7, S.L.

Manuel Murguía, 35 Bajo, 32005

OURENSE, Spain - View on map

-

View on map

Dental Bauer GmbH

Curiestraße 4, Geb. Step 2, 70563

Stuttgart, Germany -

View on map

Dental Bauer GmbH

Ernst-Simon-Straße 12, 72072

Tübingen, Germany -

View on map

Dental Bauer GmbH

Alfred-Nobel-Straße 9, 86156

Augsburg, Germany -

View on map

Dental Bauer GmbH

Unterweingartenfeld 6, 76135

Karlsruhe, Germany -

View on map

Dental Bauer GmbH

Jechtinger Straße 10, 79111

Freiburg, Germany -

View on map

Dental Bauer GmbH

Max-Stromeyer-Straße 172, 78467

Konstanz, Germany -

View on map

Dental Bauer GmbH

Hans-Wilhelmi-Straße 4, 66386

St. Ingbert, Germany -

View on map

Dental Bauer GmbH

Hanauer Landstraße 172, 60314

Frankfurt am Main, Germany -

View on map

Dental Bauer GmbH

Annaberger Straße 73, 09111

Chemnitz, Germany -

View on map

Dental Bauer GmbH

Ostendstraße 196, 90482

Nürnberg, Germany -

View on map

Dental Bauer GmbH

Prüfeninger Straße 35, 93049

Regensburg, Germany -

View on map

Dental Bauer GmbH

Dessauer Straße 13-15, 80992

München, Germany -

View on map

Dental Bauer GmbH

Hafenstraße 14, 59067

Hamm, Germany -

View on map

Dental Bauer GmbH

Vollrath-Müller-Straße 10, 33330

Gütersloh, Germany -

View on map

Dental Bauer GmbH

Tiefenbroicher Weg 15, 40472

Düsseldorf, Germany -

View on map

Dental Bauer GmbH

Poller Kirchweg 99-101, 51105

Köln, Germany -

View on map

Dental Bauer GmbH

Kasseler Str. 62, 34277

Fuldabrück, Germany -

View on map

Dental Bauer GmbH

Koenigsallee 56, 14193

Berlin, Germany -

View on map

Dental Bauer GmbH

Daniel-Vorländer-Straße 6, 06120

Halle, Germany -

View on map

Dental Bauer GmbH

Leipziger Str. 45 b, 03048

Cottbus, Germany -

View on map

Dental Bauer GmbH

Liebigstraße 7, 39104

Magdeburg, Germany -

View on map

Dental Bauer GmbH

Gartenstraße 28, 29410

Salzwedel, Germany -

View on map

Dental Bauer GmbH

Gerhard-Stalling-Straße 41, 26135

Oldenburg, Germany -

View on map

Dental Bauer GmbH

Kronshagener Weg 105, 24116

Kiel, Germany -

View on map

Dental Bauer GmbH

Am Fördeufer 1b, 24944

Flensburg, Germany -

View on map

Dental Bauer GmbH

Werner-Otto-Straße 8, 22179

Hamburg, Germany - View on map

-

View on map

Dental Bauer Nederland B.V.

De Steenbok 12, 5215 ME

ME'S-HERTOGENBOSCH, Netherlands -

View on map

Dental Club S.p.A. Forniture Dentali

Via Alessandro Volta, 5, 35010

LIMENA (PD), Italy -

View on map

Dental Cremer

Av. das Industrias Antonio Conrado de Oliveira, 90 - Galpão 3. Rodovia Fernão Dias, 37655-0000

ITAPEVA, Brazil -

View on map

Dental Depot LLC

6/72 N.Sajaia Str., 0179

TBILISI, Georgia -

View on map

Dental Design PC.

140100, Shokhruh 27,

SAMARKAND, Uzbekistan -

View on map

Dental Direkt GmbH

Industriezentrum 106-108, 32139

Spenge, Germany -

View on map

Dental Discount

130 Rue du Moulin Vedel, 30900

NIMES, France -

View on map

Dental Dynamics Australia (IDS Trading Australia Pty Ltd)

SE 1, L1, 24-26, Carter Street,, 2141

Lidcombe, NSW, Australia -

View on map

Dental EGGERT GmbH

Württemberger Straße 14, 78628

Rottweil, Germany -

View on map

Dental Free

Rua Araguari, 359, ljs 103/104 (3° andar) Barro Preto , 30190-110

BELO HORIZONTE, Brazil -

View on map

Dental Globo

Rua Guimarães Lima, 413 - Qd. 22 - Lote 01 - Sala 01 - Vila Rosa , 74843-580

GOIÂNIA, Brazil -

View on map

Dental Health Products, Inc.

2614 N. Sugar Bush Rd, WI 54229

NEW FRANKEN, United States of America -

View on map

Dental ITA

Rua Gamboa, 287 - Paraíso , 09190-670

SANTO ANDRÉ, Brazil -

View on map

Dental Inc.

31 Rue d’Armagnac, 33800

BORDEAUX, France -

View on map

Dental Industrieservice Luik

Am Sportplatz 1, 73269

Hochdorf, Germany -

View on map

Dental Logistik GmbH

Delmenhorster Straße 14, 28816

Stuhr, Germany -

View on map

Dental Muller

Rua Hercules Gallo, 1430 , 95020-330

CAXIAS DO SUL, Brazil -

View on map

Dental Mussi

RUA ALAGOAS, 381 - Centro , 86.010520

LONDRINA, Brazil -

View on map

Dental Noord

Wismastate 3, 8926

RA Leeuwarden, Netherlands -

View on map

Dental Paulista

Rua Lamenha Lins, 2150 - Rebouças, 80220-080

CURITIBA, Brazil -

View on map

Dental Plus USA

1188 W 10400 S, 84095

South Jordan, UT, United States of America -

View on map

Dental Progresso

Avenida Orozimbo Maia, 337 - Vila Itapura , 13023-002

CAMPINAS, Brazil - View on map

-

View on map

Dental Protetic

Rua Professora Célia Roncatti Diniz, 405 Jd. Maracanã , 15092-060

SAO JOSÉ DO RIO PRETO, Brazil -

View on map

Dental Prótese

Rua José Jacques, 96 térreo , 88.020-080

FLORIANÓPOLIS, Brazil -

View on map

Dental RC

Praça Saens Peña, 55 Cjto. 403 - Tijuca , 20520-090

RIO DE JANEIRO, Brazil -

View on map

Dental Shop NPT LIRI

Rr. Hamez Jashari 29, 10000

PRISHTINA, -

View on map

Dental Tiradentes

Rua Tupis, 343 -SI. 201 - Centro , 30190-905

BELO HORIZONTE, Brazil -

View on map

Dental Trade Mart Pvt. Ltd

632, Shibbanpura, opp. C-Block Park Patel Nagar 2nd,, 201001

Ghaziabad, India -

View on map

Dental Trey Srl

Via Partisani, 3, 47016

FIUMANA (FC), Italy -

View on map

Dental Triângulo

CNB,2 - Lotes 10/11 Lojas 13 e 15 - Taguatinga Norte, 72115-025

BRASÍLIA, Brazil -

View on map

Dental Union

Postfach 30 01 69, 63088

Rodgau, Germany -

View on map

Dental-Depot Wolf+Hansen Dental-Med. Großhandlung GmbH

Schönhauser Allee 188, 10119

Berlin, Germany -

View on map

Dental-Medical d.o.o.

Meljska cesta 83, 2000

MARIBOR, Slovenia - View on map

- View on map

-

View on map

DentalEZ

301 Lindenwood Drive, Suite 100, PA 19355

Malvern, United States of America -

View on map

DentalRunner Co., Ltd.

2F, 855, Buil-ro, Gurogu,, 08261

Seoul, Korea, Republic of -

View on map

Dentalbiolux International SPRL

Chaussée de Haecht, 547 Haachtsesteenweg, 1030

BRUXELLES, BelgiumT: 003227351277 -

View on map

Dentalcomm S.r.l.

Via Strobino 59/61, 59100

PRATO (FI), Italy -

View on map

Dentalhandel & Technik Herwig Bindreiter

Franzosenhausweg 30a, 4030

LINZ, Austria -

View on map

Dentalia d.o.o.

Celovška cesta 201, 1000

LJUBLJANA, Slovenia -

View on map

Dentalinov

8, Place du Maréchal Juin, 92130

ISSY LES MOULINEAUX, France -

View on map

Dentalloys SRL

Via E. Che Guevara snc, 70023

GIOIA DEL COLLE (BA), Italy - View on map

-

View on map

Dentalmaster Lda.

Rua A. Maria da Costa, 379 Z. I. da Maia Setor IV, 4470-460

MAIA, Portugal -

View on map

Dentalservice Gebert e.k.

Margetshöchheimer Str. 80, 97299

Zell, Germany -

View on map

Dentaltorino S.r.l.

Via Villarfocchiardo, 29, 10139

TORINO (TO), Italy - View on map

-

View on map

Dentamed (CR) spol. s.r.o.

Pod Lipami 2602/41, 13000

Praha 3, Czechia - View on map

-

View on map

Dentasvet Ltd.

6, Veliki Preslav Str., 5000

VELIKO TURNOVO, Bulgaria -

View on map

Dentatechnica Ltd.

Blvd. Andrey Lyapchev No. 66, 1799

SOFIA, Bulgaria -

View on map

Dentech Innovations PR

Calle 13 A 13 Urb. Royal Town, 00956

BAYAMON/PUERTO RICO, -

View on map

Dentech Innovations US

1562 NW 89th Ct , 33172

Miami, FL, United States of America -

View on map

Denthèmes SARL

9904 Rue du Relais, 54840

VELAINE EN HAYE, France -

View on map

DentiService Tecnik, S.L.

C/ Mollerusa, 12, 25132

BENAVENT DE SEGRIÀ (LÉRIDA), Spain -

View on map

Dentidis SARL

8 Chemin des Tard-Venus, Parc de Moninsable, 69530

BRIGNAIS, France - View on map

-

View on map

Dentival, S.L. Depósito Dental

Plaza Vicente Iborra, 6 - Bajo dra., 46003

VALENCIA, Spain -

View on map

Dentotal Protect SRL

Splaiul INDEPENDENŢEI, Nr. 319L, CLĂDIREA BRUXELLES OFFICE, BUILDING (CORP B), CAMERA 2, Etaj 1, 060044

BUCHAREST, Romania - View on map

-

View on map

Dentspro India Private Limited

3355/ 1 K.R.Road Banashankari 2nd Stage, 560070

BANGALORE, India -

View on map

Dentstore SRL

Strada Tepes Vodă 89, 021523

BUCHAREST, Romania -

View on map

Deon De Lange Dental CC

27 Zandwyk Park, Old Paarl Road, 7646

PAARL, WESTERN CAPE, South Africa -

View on map

Deppe Dental GmbH Dental-Depot

Owiedenfeldstraße 6, 30559

Hannover, Germany -

View on map

Depósito Dental Denteco, S.A.

13 Avenida "B" 24-49, Zona 13 NIT 448232-8, 01013

CIUDAD DE GUATEMALA, Guatemala -

View on map

Depósito Dental Krobalto

RUC: 0990031061001 Av. Kennedy #211 y Francisco Boloña, 090510

GUAYAQUIL, Ecuador -

View on map

Diferencial Distribuições

Rua Miguel Gonçalves, 215 - Montese, 60420480

FORTALEZA, Brazil -

View on map

Digital Dental Distribution SASU

36 rue de la Picterie, 59310

FAUMONT, France - View on map

-

View on map

Dislabo

6, rue Jules Verne ZA BEG Runio, 56530

QUEVEN, France -

View on map

Distribuidora Medica Dental Centroamericana S.R.L.

Col Las Mesetas 15, Calle 23 ave.,

SAN PEDRO SULA, Honduras -

View on map

Dorina Mele Co. sh.p.k.

Rruga Prokop Myzeqari Nr. 8, Pallati. 90/1, Blloku i Zyrave,

TIRANA 1000, Albania -

View on map

Drive Dental Incorporation CO., LTD

627 Soi Ladprao 101 Ladprao Rd. Khlong Chaokhun Sing Wangthonglang, 10310

BANGKOK, Thailand -

View on map

Dumontet-Husson

24 Ave. Joannes Masset, 69009

LYON, France -

View on map

Durodent Dental Supplies

Unit 6/ 51 Jersey Road, Bayswater, 3153

VICTORIA, AustraliaT: +61397206700 -

View on map

Dôme Technic Dentaire Sarl

17, rue du pre la reine, 63100

CLERMONT-FERRAND, France - View on map

-

View on map

E. B. Pareja Lecaros S.A.

Los Negocios 115 – Surquillo RUC: 20100579228,

LIMA 34, Peru -

View on map

EDWJEL, C.A.

Avenida Montes de Oca, Centro Comercial Caribbean Plaza, Módulo 9, Local 190, 2001

VALENCIA, EDO. CARABOBO, Venezuela (Bolivarian Republic of) -

View on map

EFF Dental Ibérica, Lda.

Avenida da Igreja, 28, RC/Dto., 2480-301

PORTO DE MÓS, Portugal -

View on map

ENHANCE DENTAL GROUP SDN BHD

Y-b1-06-07 Crimson Commerical, Jalan PJU1A/41, 47301

SELANGOR, Malaysia -

View on map

EURL EMS - Ecrement

29, Rés. Ciboneye a Bergevin, BP 7 Messageries, 97110

POINTE-A-PITRE - F.W.I., -

View on map

East West Enterprises Pvt Ltd

Galkopakha, Thamel,, 44600

Kathmandu,, Nepal -

View on map

Eastland Dental Supplies Pte Ltd

60 Kaki Bukit Place 01-08, Eunos Techpark, 415979

SINGAPORE, SingaporeT: +6562965660 -

View on map

Ebda-dent

Karrada - Sharqia - Attar st., Q. 905 st. 11 bldg. no. 84 - 1st floor,

BAGHDAD, Iraq -

View on map

Elie Mina Dental SARL

Bouchrieh United Court Center Dora Highway,

BEIRUT, Lebanon -

View on map

Ellequadro di Luca Loiodice

Viale Antonio Salandra 1/L, 70124

BARI, Italy -

View on map

Elpana Trading Ltd. Importers - Exporters

6 A, Gregoris Afxentiou Avenue Aytos Dhometios, 1702

NICOSIA, Cyprus -

View on map

Equipement Medico Dentaire sarl

Fréres Bekkouche E.M.D. Zone d'activite ain smara N°26 - C, 25000

CONSTANTINE, Algeria -

View on map

Esthetic Professionals

18981 Ventura Blvd, CA 91356

Tarzana, United States of America -

View on map

Eunice Soluções

Av. Otávio Rocha, 134 3º andar - Centro , 90020-150

PORTO ALEGRE, Brazil -

View on map

Euromax-Monaco

20, Boulevard Rainier III, 98000

MONTE CARLO, France -

View on map

Euromax-Monaco SAM Alias Medical

4/6 av. Albert II - Bloc B, 98000

MONTE CARLO, Monaco -

View on map

Europ Dentaire Service Sarl

160 La Place, 59470

HERZEELE, France -

View on map

Evgeny Stefanov ES Ltd.

Skobelev 10 Blvd. Ap. 1, 1463

SOFIA, Bulgaria -

View on map

Evident Dental

Rua Marechal Deodoro, 503 - Cjt. 103 - Centro , 80020-320

CURITIBA, BrazilT: (41)33225069 -

View on map

Evident SARL

7 Avenue de la pointe, 33610

CANÉJAN, France -

View on map

Excel Dental Ltd.

Unit 101 618 East Kent Avenue, South,

VANCOUVER, B.C. V5X 0B1, Canada -

View on map

FDC santé FOURNITURES DENTAIRES CAENNAISES SAS

181 rue Marie Curie, 14200

HEROUVILLE ST.CLAIR, France -

View on map

FEED Corporation

19th floor, Queen's Tower B, 3-3 Minatomirai 2-chome, Nishi-ku, 220-6119

Yokohama, Japan -

View on map

Farzat Chatta

P.O. Box 4588,

DAMASCUS, Syrian Arab Republic -

View on map

Fenix Dental s.r.o.

U Pekařky 484/1a, 18000

PRAHA 8 - LIBEŇ, Czechia - View on map

- View on map

- View on map

-

View on map

Flume Technik GmbH

Hachestraße 66, 45127

Essen, Germany -

View on map

Foerster Electronics Inh. Wilfried Förster

Rüblandener Str. 35, 91242

Ottensoos, GermanyT: 09123 999903 -

View on map

Fondaco Pte Ltd

7 Kaki Bukit Road #03-06 Eunos Techno Link, 415937

Singapur, SingaporeT: +6563922806 - View on map

-

View on map

Forestadent France

Rue Jacques Peirotes 5, 67000

STRASBOURG, France -

View on map

Forestadent USA

3451 Rider Trail South , MO 63045

Earth City, United States of America -

View on map

Forsen Enterprise Co., Ltd.

9F., No. 23, Longjiang Rd., 104

TAIPEI CITY, - View on map

- View on map

-

View on map

Funck Dental-Medizin GmbH Dental Depot

Fritz-Frey-Straße 16, 69121

Heidelberg, Germany -

View on map

Futura-Dent GmbH

Tannenweg 3, 72141

Walddorfhäslach, Germany -

View on map

Futura-Dent GmbH

Eckenheimer Landstraße 60 b, 60318

Frankfurt, Germany - View on map

-

View on map

Futura-Dent GmbH & Co. KG Dental-Med.-Großhandel

Daimlerstraße 8, 45891

Gelsenkirchen, Germany -

View on map

Futura-Dent GmbH Dental Depot

Birzentalstraße 15, 53177

Bonn, Germany -

View on map

GARG DENTAL PVT LTD

PAN NO 300217054 127, GAIRIDHARA, 44600

KATHMANDU, Nepal -

View on map

GLS Logistik Dental Handel GmbH & Co KG

Richard-Roosen-Str. 10, 34123

Kassel, Germany -

View on map

GUIZHOU SHENGSHI HUAGUANG MEDICAL DEVICE CO. LTD.

No. 10-1, Unit 2, Fuyuan Shiji Medical Logistics Park Phase II, No. 22 Fuyuan Norh Road Nanming District, Guiyang City, 550000

Guizhou, China -

View on map

Garland Dental Services

850 N. Dorothy Drive, Suite 502, 75081

RICHARDSON, TX, United States of America -

View on map

Gatto Vittorio

Via Dante Alighieri 21, 00030

SAN VITO ROMANO, Italy -

View on map

Gebr. Genal

Georg-Hallmaier Straße 2, 81369

München, Germany - View on map

-

View on map

Gerhó S.P.A:/A.G.

Via L. Negrelli 4, 39100

BOLZANO, Italy -

View on map

Gesimed Asistencia Técnica, S.L.

Avda. Celanova 139, Bajo, 32890

BARBADÁS/OURENSE, Spain -

View on map

Goldentav Unipessoal Lda.

Rua da Bélgica, 1304, 4400-045

CANIDELO - VILA NOVA DE GAIA, Portugal -

View on map

Griesauer Dental Dentalwarenvertrieb

Paletzgasse 36-38 / Lokal B3, 1160

WIEN, Austria -

View on map

Grossi Dental Trade S.R.L.

Via Vittorio Emanuele Orlando 30/A, 43126

Parma, Italy -

View on map

Grupo Checa y Navarro, S.L.

C/ Tomás Higuera, 12 Local izqda., 50013

ZARAGOZA, Spain -

View on map

HENRY SCHEIN CANADA

345 TOWNLINE ROAD SS4, L0S 1J0

NIAGARA ON THE LAKE, ON, Canada -

View on map

HLZ Logistik GmbH

Am Neumarkt 34, 22041

Hamburg, Germany -

View on map

Hans Krum Dental-Depot

Schmolzstraße 20, 41462

Neuss, Germany -

View on map

Helmut Arnim GmbH

Am Moosfeld 53, 81829

München, Germany -

View on map

Henry Schein (UK) Holdings Ltd.

Medcare House, Centurion Close, Gillingham Business Park, ME8 0SB

GILLINGHAM/KENT, United Kingdom of Great Britain and Northern Ireland -

View on map

Henry Schein Austria GmbH

Sterneckstr. 37/4, 5020

SALZBURG, Austria -

View on map

Henry Schein Dental

Garnisonsstraße 17/3 - C1, 4020

LINZ, Austria -

View on map

Henry Schein Dental

St. Peter Gürtel 4/2, 8042

GRAZ, Austria -

View on map

Henry Schein Dental

Langer Weg 15, 6020

INNSBRUCK, Austria - View on map

-

View on map

Henry Schein Dental Deutschland GmbH

Willy-Brandt-Straße 3, 76275

Ettlingen, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Hamburger Str. 24, 34134

Kassel, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Untere Jakobermauer 11, 86152

Augsburg, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Ullsteinstr. 73, Gebäude 3, 12109

Berlin, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Universitätsallee 5, 28359

Bremen, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Londoner Bogen 6, 44269

Dortmund, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Hanferstraße 1, 79108

Freiburg, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Avenwedder Straße 210, 33335

Gütersloh, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Essener Straße 2, 22419

Hamburg, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Podbielskistr. 333, 30659

Hannover, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Westring 453-455, 24118

Kiel, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Rolandstr. 5, 45128

Essen, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Dr. Emil-Brichta-Straße 5, 94036

Passau, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Käthe-Kollwitz-Str. 13, 66115

Saarbrücken, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Industriestraße 6, 70565

Stuttgart, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Eberhardtstraße 3, 89073

Ulm, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Emanuel-Leutze-Straße 8, 40547

Düsseldorf, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Ulmer Straße 123, 73037

Göppingen, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Nordostpark 32-34, 90411

Nürnberg, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Im Breitspiel 19, 69126

Heidelberg, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Telemannstraße 1, 1. OG, 95444

Bayreuth, Germany - View on map

-

View on map

Henry Schein Dental Deutschland GmbH

Theresienhöhe 13, 80339

München, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Großer Brockhaus 5, 04103

Leipzig, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Theodor-Heuss-Straße 66 a, 37075

Göttingen, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Weiherbachstraße 2, 84034

Landshut, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Wismarsche Straße 390, 19055

Schwerin, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Hufelandstraße 8 a, 03050

Cottbus, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Hüfferstraße 52, 48149

Münster, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Schubertstr. 21, 01307

Dresden, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Hochstraße 7, 95028

Hof, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Unterm Markt 1, 07743

Jena, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Monzastr. 2a, 63225

Langen, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Im Gewerbepark D 75, 93059

Regensburg, Germany -

View on map

Henry Schein Dental Deutschland GmbH

Lyoner Straße 20, 60528

Frankfurt, Germany -

View on map

Henry Schein España, S.L.

Avenida de la Albufera, 153, 28038

MADRID, Spain -

View on map

Henry Schein France

2-4 Rue de la Flottière, 37304

JOUE LES TOURS CEDEX, France -

View on map

Henry Schein Halas

Unit 1-4, 44 O'Dea Avenue, 5003

ALEXANDRIA NSW, Australia -

View on map

Henry Schein Hong Kong Ltd.

Unit B, 21 Floor, 78 Hung To Road Kwun Tong,

KOWLOON, -

View on map

Henry Schein INC.

135 Duryea Road, 11747

MELVILLE, NY, United States of America -

View on map

Henry Schein Krugg S.r.l.

Via dei Lavoratori, 7, 20090

BUCCINASCO (MI), Italy -

View on map

Henry Schein N.V. Belgique

Luchthavenlaan 20, 1800

VILVOORDE, Belgium -

View on map

Henry Schein Services GmbH

Monzastr. 2a, 63225

Langen, Germany -

View on map

Henry Schein Sunshine (Beijing) Medical Device Co. Ltd.

Room 808-811, DongCheng Guoji AoYi Building, No. 98 Huang He Dado, Gao Xin District , 05000

He Bei (Shijiazhuang), China -

View on map

Henry Schein s.r.o.

Cernokostelecka 24, 10000

PRAGUE, Czechia -

View on map

Hermann Steffen GmbH Rep.-Service

Flachsland 35, 22083

Hamburg, Germany -

View on map

Herminio Emigdio Ramírez Ramírez

Calle Marsella 445, Colonia Deitz, RARH6408052D7, 44158

GUADALAJARA, JAL., Mexico -

View on map

Hess & Schmitt Dental Depot

Engelstraße 1, 54292

Trier, Germany -

View on map

High Technology for Dental Supplies

Al-Sarrafiya, near Al-Sarrafiya Bridge beside Althakira Librar, 10053

BAGHDAD, Iraq -

View on map

Hospiland Healthcare

Bawshar Street Luxury Tower Office No. 5, 113

MUSCAT, Oman -

View on map

IDS Denmed PVT Ltd.

A - 20/3, Mayapuri Industrial Area Phase - I, 110064

NEW DELHI, India -

View on map

INDENT S.A.

Plaza San Jorge, Módulo #6, De la Loteria Nacional 1C, Sur, ½C, Oeste, Entrada principal UAM, Camino de Oriente, 14157

MANAGUA, Nicaragua -

View on map

INTERDENT d.o.o.

Opekarniška cesta 26, 3000

CELJE, Slovenia -

View on map

INTERDENT d.o.o.

Vinogradski odvojak 2d, 10431

Sveta Nedelja, Croatia -

View on map

INTERDENT d.o.o.

Egipatska 22, 11070

Novi Beograd, Serbia -

View on map

INTERDENT d.o.o.

Foerstrova 12, 10000

Praga, Czechia -

View on map

Ideal Dent

566 Chemin de Sahuquet, 31220

MONDAVEZAN, France -

View on map

Ident Prime LLC

Ave Povitroflotskiy 90, office 208 , 02000

KIEV, Ukraine -

View on map

Imagine Canada Office

889 Vaughan Ave #107, V1Y 0H8

Kelowna, BC, Canada -

View on map

Imagine USA

607 Euclid Street, 92832

Fullerton, CA, United States of America - View on map

-

View on map

Innova 4D Dominicana

Calle Rafael Hernández #20, Naco,

SANTO DOMINGO, Dominican Republic -

View on map

Inspe LLC

Brativ Mikhnovskykh Str. 42, 79018

LVIV, Ukraine -

View on map

Intermed Dentaire

17 bis Rue Georges Claude - Ducos, BP 1411, 98845

NOUMEA CEDEX, - View on map

-

View on map

Intertrading Dental AG

Fischhauserstraße 8a, 8722

KALTBRUNN, Switzerland -

View on map

Ivoclar Vivadent (NZ) Ltd.

PO Box 303011, North Harbour, 0751

AUCKLAND, New Zealand -

View on map

Ivoclar Vivadent Marketing India Private Ltd.

Emmar Digital Greens Unit No 824/825/826/827, 8th Floor, Tower A, Sector - 61, Golf Course Extension Road, Gurugram, 122011

HARYANA, India -

View on map

Ivoclar Vivadent Pty Ltd.

PO Box 367 Noble Park North, 3174

VICTORIA, Australia -

View on map

Japan Dental Supply Co. Ltd.

1-19-5 Ishiwara, Sumida-Ku,

TOKYO 130-0011, Japan -

View on map

Jarident, s.r.o.

Podtatranská 2501, 05801

POPRAD, Slovakia -

View on map

Jean-Franck Matdent SARL

8, chemin de la Caille, 31750

ESCALQUENS, France -

View on map

Jeneric-Pentron Deutschland GmbH

Raiffeisenstraße 18, 72127

Kusterdingen, Germany -

View on map

Jiloi Ahtar LLC

Naberezhnaja str. 27, 734003

DUSHANBE, Tajikistan - View on map

-

View on map

João Reis Dental

Rua Afonso Celso, 76 - Vila Mariana , 04119-000

SÃO PAULO, Brazil - View on map

-

View on map

Kaladent AG

Schachenstrasse 2, 9016

St. Gallen, Switzerland -

View on map

Kaladent Urdorf

Steinackerstrasse 47, 8902

URDORF, Switzerland -

View on map

Karl Fischer Werkzeuge GmbH

Berliner Straße 18, 75172

Pforzheim, Germany -

View on map

Karlsson, Lukas D.

Síðumúla 27a, 108

REYKJAVIK, Iceland - View on map

- View on map

- View on map

-

View on map

Klos Dental u. Labortechnik

Birkenweg 26, 66127

Saarbrücken, Germany -

View on map

Kodent Dental Supply

1525 N. 4th Street, WA 98057

RENTON, United States of America -

View on map

Krbec Dent s.r.o.

Únesovská 20/2114, 32300

PLZEN, Czechia -

View on map

Kuss Dental, S.L.

C/ Isabel Colbrand, 10-12, Nave 95, 28050

MADRID, Spain -

View on map

Köhler Dentalvertrieb

Grimmstr. 43, 91154

Roth-Eckersmühlen, Germany -

View on map

LIANG-JIE MEDICS LTD.GUANGZHOU.CHINA

Room608,Building 2,Nantai Road 168#,Haizhu District,,

Guangzhou, Guangdong Province, China -

View on map

LONGHAI ST CO., LTD.

103 Le Dinh Tham, Tan Quy Ward Tan Phu District, 70000

HO CHI MINH CITY, Viet Nam -

View on map

LUCH LTD.

50 Satpaev Street, 050057

ALMATY, Kazakhstan -

View on map

Leiva's Dental S.A.S.

NIT: 800.080.191-2 Carrera 15 #92-29, Oficina 804, 110141

BOGOTÁ, DC, Colombia -

View on map

Lifco Dental AB

Verkmästaregatan 1, 74585

ENKÖPING, Sweden -

View on map

Lizydent Kft.

Botond u.10, 1134

BUDAPEST, Hungary -

View on map

Lohrmann Dental GmbH Dental Depot

Hildesheimer Str. 35, 30169

Hannover, Germany -

View on map

Loran Srl

Via della Lira, 397, 31053

PIEVE DI SOLIGO (TV), Italy -

View on map

M+W Dental Müller & Weygandt GmbH

Reichardsweide 40, 63654

Büdingen, Germany -

View on map

M+W Dental Swiss AG

Länggstr. 15, 8308

ILLNAU, Switzerland -

View on map

MAECOLUX S.A.

54 Rue de la Montagne, 3259

Bettembourg, Luxembourg -

View on map

MN Health Inc.

14008 Park East Circle Suite 100, VA 20151

Chantilly, United States of America -

View on map

MP Dental UAB

Ukmergès Str. 300 C - 65, 06143

VILNIUS, Lithuania -

View on map

MPS DENTAL GMBH

HORBELLER Str. 9, 50858

Köln, Germany - View on map

-

View on map

Madina Dental Supplies

Sport City, Lauozi Building No. 11, P.O. Box 19070, 11196

AMMAN, Jordan - View on map

-

View on map

Manfred Heinze Dental GmbH

Hohmannstr. 7a, 04129

Leipzig, Germany -

View on map

Manolito Dental SRL

Pdte. Hipólito Irigoyen 1A Zona UASD,

SANTO DOMINGO, Dominican Republic - View on map

-

View on map

Marrodent Sp. z.o.o.

Ul. Krasinskiego 31, 43300

BIELSKO BIALA, Poland -

View on map

Massilia Dental by DL Groupe

31 Avenue de la Savoie, 13180

GIGNAC LA NERTHE, France -

View on map

Master Tecnik S.r.l.

Via Guido Rossa, 38, 40033

CASALECCHIO DI RENO (BO), Italy -

View on map

Medent Co., Ltd.

37 Bau Cat 3, Ward 14 Tan Binh District,

HO CHI MINH CITY, Viet Nam -

View on map

Medent GmbH Sachsen Dental-Depot

Schönherrstraße 8, 09113

Chemnitz, Germany -

View on map

Medical & Pharmaceutical Services Bashir Shakib Al-Jabri & Co. Ltd.

P.O. Box 9584, 21423

JEDDAH, Saudi Arabia -

View on map

Medical Intertrade

Marsala Tita 30/III, 71000

Sarajevo, Bosnia and Herzegovina -

View on map

Medical Intertrade d.o.o.

Dr. Franje Tudmana 3, 10431

SVETA NEDJELJA, Croatia -

View on map

Medident Exim SRL

Str. Traian Nr. 109, 500332

BRASOV, Romania -

View on map

Medipro International d.o.o.

Neznanog Junaka 37, 11040

BEOGRAD, Serbia -

View on map

Meditrans SP. zo.o. sp.k.

Ul. Podlasie 16C, 25-108

KIELCE, Poland -

View on map

Medix Supplier

Unit 29&30, 1st Floor, Simpang 88, Kampong Kiulap, Bandar Seri Begawan BE 1518, BE 1518

DARUSSALAM, Brunei Darussalam - View on map

-

View on map

Medtreq for Medical Devices and Supplies, LLC

Office #21 Building 585 Road 2018 AlHoora Block 320,

MANAMA, Bahrain -

View on map

Medtronicam Trading Co., Ltd.

No. 8, St. M02, Phum Toul Pongro, Chaom Chau 1, PurSenChey, 120909,,

Phnom Penh, Cambodia - View on map

- View on map

-

View on map

Meridian Joint Stock Company

126 Sumskaya Str., 61023

KHARKIV, Ukraine -

View on map

Metaldent S.r.l.

della Valle dei Fontanili 15, 00168

ROMA, Italy -

View on map

Middle East International Trading Co. Ltd.

7 Amin Al-Kholy Str. 5240 Heliopolis West, 11511

CAIRO, Egypt -

View on map

Mikran SP. z o.o.

Wojskowa 3/L4, 60-792

POZNAN, Poland -

View on map

Minerva S.r.L

Via Aldo Moro, 2, 95030

S.AGATA LI BATTIATI (CT), Italy -

View on map

Miroslav Kasana - SANUS

Pod Hliníkom 27, 95141

LUZIANKY, Slovakia - View on map

-

View on map

Moltodent Suministros Médicos, S.L.

C/ Andujar, 4 - Local, 23008

JAEN, Spain -

View on map

Multi-Service Dentaire

8 route d'Escalquens, 31320

CASTANET TOLOSAN, France -

View on map

Multident Dental GmbH

Oldenburger Allee 6, 30659

Hannover, Germany -

View on map

Multident Dental GmbH

Breitenbachstr. 10, 13509

Berlin, Germany -

View on map

Multident Dental GmbH Dental Depot

Königsstieg 94, 37081

Göttingen, Germany -

View on map

Multident Dental GmbH Dental-Depot

Edewechter Landstraße 148, 26131

Oldenburg, Germany -

View on map

Multident Dental GmbH Niederlassung Paderborn

Borchener Str. 163, 33106

Paderborn, Germany - View on map

- View on map

- View on map

-

View on map

New Dental Supply

14747 Artesia Blvd.Suite 5K, 90638

La Mirada, CA, United States of America -

View on map

New Galetti e Rossi S.R.L. Forniture Dentali

Via Cenisio 20, 20154

MILANO, Italy -

View on map

Noor Alhuda Trading

Office 107, Al Muhairi Plaza, Al Khabaisi Area, Deira,

DUBAI, United Arab Emirates - View on map

-

View on map

Nordenta Handelsges. mbH Kred.buchhaltung

Am Neumarkt 34, 22041

HAMBURG, Germany -

View on map

Nowak Dental Supplies Inc.

6716 Highway 11 North, 39426

CARRIERE, MS, United States of America -

View on map

NuvoDent Co., Ltd.

419/165 Tippawan 1, Moo 5 Soi 14, Theparak Rd., Theparak, Muang, 10270

Samutprakarn, Thailand -

View on map

Odontobom

Rua Demócrito de Souza Filho, 503 Madalena, 50610-120

RECIFE, Brazil -

View on map

Odontomedica SARL

Zone d'activité Ain smara tranche I n° 26 - A, 25140

CONSTANTINE, Algeria -

View on map

Odontos LLC

Ul. Mamed Araza 50C, AZ1106

BAKU, Azerbaijan -

View on map

Odontoville

Rua Timbó, 90 - América, 89204-050

JOINVILLE, Brazil -

View on map

Olympic Dental S.A.

CUIT: 30-68622369-4 Manuel R. Trelles 2749, 1416

BUENOS AIRES, Argentina -

View on map

Omega Dent Dentalfachhandel

Brunnenweg 7, 89429

Bachhagel, Germany - View on map

-

View on map

Otoplastic AG

Merkurstr. 4, 9000

ST. GALLEN, Switzerland -

View on map

Oyudent LLC

63/1,19-r khoroo, Bayangol dist, 16064

ULAANBAATAR, Mongolia - View on map

-

View on map

P&S and Company LLC

1701 W 135th St Unit A, CA 90249

Gardena, United States of America -

View on map

PACOTECH Company

Al Qassab Bulding No. 155/1/140 Str. 18 Section 204 Mustaufi or,

ERBIL, Iraq -

View on map

PROMEDIKA LTD.

Ul. Sv. Kiril i Metodij br. 50, p. fah 122, 1000

SKOPJE, North Macedonia -

View on map

PROWECARE TRADING SDN BHD

5A, Jalan Besar,, 43300

Seri Kembangan, Selangor,, Malaysia -

View on map

PT. Fondaco Jayatama

APLTower, Podomoro City 27th Floor, Suite 2 Jl. Letjen S. Parman Kav- 28 JAKARTA,11470 Indonesia, 11470

JAKARTA, Indonesia - View on map

-

View on map

PX France Sarl

70, impasse de la prairie Est ZAC des Bromines Est, 74330

SILLINGY, France -

View on map

Pareja Lecaros Chile S.A.

RUT: 99.545.700-8 Calle Balmoral No. 309, Local 207-208 Las Condes,

SANTIAGO DE CHILE, Chile -

View on map

Patterson Dental Canada

1205 Henri Bourassa West,

MONTREAL, QUEBEC H3M 3E6, Canada -

View on map

Patterson Dental USA

1031 Mendota Heights Rd., 55120

MST. PAUL, MN, United States of America -

View on map

Paveas Dental GmbH & Co. KG

Bahnhofstraße 24-26, 56068

Koblenz, Germany -

View on map

Pearson Dental Supply Co.

13161 Telfair Avenue, 91342

SYLMAR, CA, United States of America -

View on map

Plandent AS

Ostensjoveien 27 Postboks 6082 Etterstad, 0601

OSLO, Norway -

View on map

Plandent B.V.

Ravenswade 54K , 3439 LD

NIEUWEGEIN, Netherlands -

View on map

Plandent GmbH

Dresdner Straße 81-85, 1200

WIEN, Austria -

View on map

Plandent GmbH & Co. KG

Schuckerstraße 21, 48153

Münster, Germany -

View on map

Plandent GmbH & Co. KG

Steinbachstr. 13 , 94036

Passau, Germany -

View on map

Plandent GmbH & Co. KG

Europaplatz 12, 70565

Stuttgart, Germany - View on map

-

View on map

Plandent GmbH & Co. KG

Nordsternstraße 65, 45329

Essen, Germany -

View on map

Plandent GmbH & Co. KG

Heinz-Nixdorf Straße 14a, 41179

Mönchengladbach, Germany - View on map

-

View on map

Plandent GmbH & Co. KG

Landsberger Str. 428, 81241

München, Germany -

View on map

Plandent GmbH & Co. KG

Am Borsigturm 100 , 10507

Berlin, Germany -

View on map

Plandent GmbH & Co. KG

Freie-Vogel-Str. 393, 44269

Dortmund, Germany -

View on map

Plandent GmbH & Co. KG

Pfalzgrafenstraße 43 , 67434

Neustadt, Germany -

View on map

Plandent GmbH & Co. KG

Hartmanns Au 8, 66119

Saarbrücken, Germany -

View on map

Plandent GmbH & Co. KG

Albert-Einstein Str. 6, 87437

Kempten, Germany -

View on map

Plandent GmbH & Co. KG

Mallaustraße 61, 68219

Mannheim, Germany -

View on map

Plandent GmbH & Co. KG

Rosenheimer Str. 70, 83059

Kolbermoor, Germany -

View on map

Plandent GmbH & Co. KG

Große Elbstraße 145e, 22767

HAMBURG, Germany -

View on map

Plandent GmbH & Co. KG

Nadorster Str. 222, 26123

Oldenburg, Germany -

View on map

Plandent GmbH & Co. KG

HIldesheimer Straße 27, 38114

Braunschweig, Germany -

View on map

Plandent GmbH & Co. KG

Eckendorfer Straße 2-4, 33609

Bielefeld, Germany -

View on map

Plandent GmbH & Co. KG

Ludwig-Erhard-Str. 27, 04103

Leipzig, Germany -

View on map

Plandent OY

Asentajankatu 6 B, 00880

HELSINKI, Finland -

View on map

Plandent Österreich Graz

Lauzilgasse 21-23, 8020

GRAZ, Austria -

View on map

Plandent Österreich Wals

Pannzaunweg 1b, 5071

WALS/SALZBURG, Austria -

View on map

Plast-Dent d.o.o.

Vizantijski Bulevar 35, 18000

NIŠ, Serbia -

View on map

Pooja Dental Distributors Ltd

Fair Bank Arcade, Mai Mahiu Rd, Behind T-Mall, P.O.Box 17708-00500,

NAIROBI, Kenya -

View on map

Poulson-Dental GmbH Dentalmed.-Fachhandel

Heidenkampsweg 75, 20097

Hamburg, Germany - View on map

-

View on map

Premiere Dental Sdn. Bhd.

Unit A4-12 Pusat Perindustrian KL Batu 5, Jalan Kelang Lama, 58200

KUALA LUMPUR, Malaysia -

View on map

Proclinic S.A.U.

Passeig de la Zona Franca, 111 (Torre Auditori) 4º Planta, 08038

BARCELONA, Spain -

View on map

Prodent International d.o.o.

Zvezna Ulica 2A, 1000

LJUBLJANA, Slovenia - View on map

-

View on map

Pyrenees-Dentaire

5, rue de l'Oussère, 64320

IDRON, France - View on map

-

View on map

R M P 27

245 La Grande Rue, 27230

BAZOQUES, France -

View on map

RED Dental, S.L.U.

Julian Camarillo, 23 - 3A, 28037

MADRID, Spain - View on map

-

View on map

RM Odonto

Rua São José, 50 - Centro, 14010-160

RIBEIRAO PRETO, Brazil -

View on map

RM-Dental GmbH Mühlbauer

Bahnhofstraße 26, 96117

Memmelsdorf, Germany -

View on map

RMH3 Dental

4200 Lafayette Center Dr, Suite E,, 20151

CHANTILLY, VA, United States of America -

View on map

RMO Europe

Rue Geiler de Kaysersberg, 67411

ILLKIRCH CEDEX, France - View on map

-

View on map

Rafaele Francesco

Via Lama di Cervo 117, 70022

ALTAMURA (BA), Italy -

View on map

Ratoun SARL

11 rue Alexandre Coutureau, 92210

ST CLOUD, France -

View on map

Ravstedhus ApS

Ravsted Hovedgade 51, 6372

BYLDERUP-BOV, Denmark -

View on map

Ray Purt Dental

Alma House 22 Lyall Street, 6151

SOUTH PERTH WEST. AUSTR., Australia -

View on map

Raydent Supplies Pte. Ltd.

No. 6 Ubi Road 1 #04-01 Wintech Centre, 408726

SINGAPORE, Singapore - View on map

-

View on map

Remis-Dental Ltd.

Topolya-3 Street 31/A, Office 45, 49000

DNIPRO, Ukraine -

View on map

Remschnig Siegfried

Wintschacherweg 28 a, 9073

Klagenfurt-Viktring, Austria -

View on map

Renfert USA

3718 Illinois Avenue, 60174

St. Charles, IL, United States of America -

View on map

Renfert do Brasil Comércio Ltda.

Av. Guido Aliberti, 3989 - Jd. São Caetano, 09581-680

SÃO CAETANO DO SUL/, Brazil -

View on map

Representaciones Eurodent SAS

NIT 800.219.189-7 Avenida Calle 127, 7-70, 110121

BOGOTÁ, Colombia -

View on map

Revello S.p.A.

Via Enrico Fermi,20, 37136

VERONA, Italy -

View on map

Rhone Dentaire Services

Avenue Johannes Masset 24 - BP9116, C.A. Gorge de LoupLes Passerelles, 69263

LYON CEDEX 09, France -

View on map

Ribera Maurizio

Via Pigna 104, 80128

NAPOLI, Italy -

View on map

Rodeq Dental

Cuneraweg 211, 3911RJ

Achterberg (Rhenen), Netherlands -

View on map

Roland DGA

15363 Barranca Parkway, 92618

IRVINE, CALIFORNIA, United States of America -

View on map

Roos-Dental GmbH & Co. KG

Friedensstr. 12-28, 41236

Mönchengladbach, Germany - View on map

- View on map

-

View on map

SANIDENT SAS DI WATSCHINGER PETER & CO.

Viao G Galilei 6C, 39100

BOLZANO, Italy -

View on map

SARL HORIZON DENTAL

17, RUE BENOIT FRACHON, 44800

SAINT HERBLAIN, France -

View on map

SAS MACARY Maintenance

9 Allée Euros, Tecnosud 2, 66000

PERPIGNAN, France -

View on map

SC Doriot Dent SRL

STR. DR. IOAN RAŢIU, NR. 17, 310041

ARAD, Romania -

View on map

SC TEHNODENT POKA SRL

Dr. Russel Nr. 5 Ap 35 CP, 300567

Timisoara, Romania -

View on map

SCHNEIDER & BOISSON REUNIS

5, avenue de France ZAC Secoia -Heiden BP 80029 Wittelsheim, 68803

Thann Cedex, France -

View on map

SCL Logistika d.o.o.

Štefanovečka 10, 10000

ZAGREB, Croatia -

View on map

SEE Patrick Levade

20 Rue du Nine, 40990

SAINT PAUL LES DAX, France -

View on map

SHAANXI HUANG LONG MEDICAL DEVICE CO. LTD

579 Daqing Road, Lianhu District, Xi'an city , 710077

Shaanxi, China -

View on map

SID Dental

ZA du Moulin Marcille Rue Paul Pousset, 5, 49130

LES PONTS DE CE, France -

View on map

SIGMA NET SANTE

18, Rue de l'Euro, Zone actigone 4, 74960

MEYTHET, France - View on map

-

View on map

Sadent S.A.

1st km Paianias, Markopoulou Avenue, 19002

PAIANIA ATTIKIS, Greece -

View on map

Sala Medical Complex

P.O.Box 780 Postal Code: 131,

MUSCAT, Oman -

View on map

Sanitaria Dental d.o.o.

Korčulanska 4-6, 10000

ZAGREB, Croatia -

View on map

Sanitaria dental d.o.o.

Blajburških žrtava23, 88000

Mostar, Bosnia and Herzegovina -

View on map

Sasu Phenix Dental

Saint Andre, 29520

CHATEAUNEUF DU FAOU, France -

View on map

Schuler - Dental GmbH & Co. KG Dental Depot

Johannesstr. 6-8, 89081

Seligweiler, Germany -

View on map

Schulz Medizintechnik Andrea Schulz

Auetalstr. 84, 37589

Kalefeld, Germany -

View on map

Sergo-Dental Ltd.

Babura str. 77,

TASHKENT, 100090, Uzbekistan -

View on map

Shanghai Huilong Medical Device Co., Ltd.

Room 201D, Building 11, No. 777, Longwu Road, Xuhui District,, 200232

SHANGHAI, China -

View on map

Shine Technology Company

01, 2nd floor, above Oman Air, beside takeaway, Al Sadd,

DOHA, Qatar -

View on map

Shinhung Co., Ltd.

450 Cheongpa-ro, Jung-gu, 04510

SEOUL, Korea, Republic of - View on map

- View on map

-

View on map

Silesia Dental K.Mrozek Spolka Jawna

Ul. Polna 31, 55-300

Sroda Slaska / Komorniki, Poland -

View on map

Sinco GmbH & Co. KG

Iglinger Str. 27, 86899

Landsberg am Lech, Germany -

View on map

Skillbond Direct Ltd.

8 The Valley Centre / Gordon Road / High Wycombe, HP13 6EQ

BUCKS, United Kingdom of Great Britain and Northern Ireland - View on map

-

View on map

Star Dental S.A.

RUT 3101404771 Frente a la Universidad Latina de Costa Rica Local color azul con verde, 1334-1250

SAN JOSÉ, Costa Rica -

View on map

Sté Bonfoni

85, Résidences Sipres Mourtada 2 Zone Ouest Foire extention VDN, 12000

YOFF DAKAR, Senegal -

View on map

Surya Dental

Av. Melim Jones, 823 - Lote 222 - Parque Industrial Bandeirantes, 87070-030

MARINGÁ, Brazil -

View on map

Sutter & Co. Dental

Gartenstr. 30, 26122

Oldenburg, Germany -

View on map

TBRP Group

Tena Butty, 116, Chemin de Mialouze, 26130

MONTSEGUR SUR LAUZON, France -

View on map

Taberna Dentium S.R.L.

Via Aurelia 452, 17047

VADO LIGURE (SV), Italy -

View on map

Technodent SRL

NIT: 160898020 Calle Avaroa, 158,

STA. CRUZ DE LA SIERRA, Bolivia (Plurinational State of) -

View on map

Tecnolab Assistenza S.N.C

Via Don Lorenzo Milani 14, 35020

ALBIGNASEGO (PADOVA), Italy -

View on map

Tehno Dental d.o.o.

Bulevara Vojvode Zivojina Misica 10B, 78000

BANJA LUKA, Bosnia and Herzegovina -

View on map

TehnoDental d.o.o. Podgorica

Djecevica 1-3, 81000

PODGORICA, Montenegro -

View on map

Tendenze S.R.L. Distribuzioni Dentali

Via Medaglie d'oro 59, 63900

FERMO (AP), Italy -

View on map

Terra Dent SRL

Str. Amilcar C. Săndulescu Nr. 4A, Etaj 1, Sector 6, 060859

BUCHAREST, Romania -

View on map

Terramold Solutions SRL

No. 13 Saulescu Street, 700010

IASI, Romania -

View on map

Trinity, Inc.

2600 Keslinger Rd., Unit B, 60134

GENEVA, IL, United States of America -

View on map

Tudent S.A.S.

Villa Constanza, Vda. El Abra Tel.: +57 601 878 77 79,

COTA/CUNDINAMARCA, Colombia - View on map

- View on map

-

View on map

UKR-MEDMARKET Firm Private Company

Prospekt Pobedy 9/47, 01135

KIEV, Ukraine -

View on map

URUMQI XIN EXCELLENT MEDICAL DEVICE CO. LTD.

Room 1002, 10th Floor, Block A Xingle World Trade Plaza, 460 Qitai Road,, 830000

Urumqi, China -

View on map

US Dental Depot, Inc.

522 NW 77th St., 33487

Boca Raton, FL, United States of America -

View on map

Ullmann Dentalhandel + Service

Rostocker Str. 38, 18069

Lambrechtshagen, Germany -

View on map

Umbra S.P.A. Forniture Dentali

Via Madonna Alta, 138, 06128

PERUGIA, Italy -

View on map

Unicorn Denmart Limited

Plot No. 410, Industrial Estate, Sector-53, EPIP HSIIDC, Kundli, Sonipat, 131028

HARYANA, India -

View on map

Unident-AS, S.R.L.

Bul. Stefan cel Mare, 167/1, 2004

MUN. CHISINAU, Moldova, Republic of -

View on map

United Medical Specialties Corp.

6F., No. 55, Sec. 4, Xinyi Road, Da'an District,, 106685

TAIPEI CITY, -

View on map

VI.VI.MED Srl

Via Tevere, 11, 51018

PIEVE E NIEVOLE (PT), Italy -

View on map

VITTA Scientific Technical Company

Tbilisi ave. 129, AZ1122

BAKU, Azerbaijan -

View on map

VS-Dental S.p.a.

Via della Metallurgia 6, 37139

Bassone (VR), Italy -

View on map

Van der Ven Dental

Röntgenstraße 25 / Gewerbepark OWL, 32107

Bad Salzuflen, Germany -

View on map

Vilniaus Medicinos Servisas UAB

Mindaugo 23-116, 03214

VILNIUS, Lithuania -

View on map

Vita Italia S.r.l.

Via Torino 61, 20123

MILANO, Italy -

View on map

Vix Dental

Rua Aleixo Netto, 322 Loja 4 - Santa Lucia , 29056-100

VITÓRIA, Brazil -

View on map

WHW Plastics Ltd.

Therm Road, Cleveland Street, HU8 7BF

HULL/EAST YORKSHIRE, United Kingdom of Great Britain and Northern Ireland -

View on map

WOD

4 Rue Pierre Georges Latécoère, 33700

MERIGNAC, France - View on map

-

View on map

Warner Tech-care Products, LLC

3796 Dunlap St N, MN 55112

Arden Hills, United States of America -

View on map

Wendt Dental Service GmbH

Hermann-Drescher-Weg. 2, Abteil 6I, 45329

Essen, Germany -

View on map

Western Equipments And Allied Pvt. Ltd.

Oberoi Garden Estates, B-3073, 3074,B-Wing 3rd Floor, Adjacent to Chandivali Studio, Chandivali, ANDHERI (E), 400072

Mumbai, India -

View on map

Wohlwend AG

Platta 52, 9488

SCHELLENBERG, Liechtenstein -

View on map

Wolfgang Hasse Dentaltechn. Geräte

Hinrichsdorfer Straße 4, 18146

Rostock, Germany - View on map

-

View on map

Wolfgang Zibis Dentalhandel

Grunewaldstraße 6 a, 12165

Berlin, Germany -

View on map

Wright Health Group Ltd.

Dunsinane Industrial Estate, Kingsway West, DD2 3QD

DUNDEE, United Kingdom of Great Britain and Northern Ireland - View on map

-

View on map

YSHGYN MEDICAL AND LAB. EQUIPMENTS

Oguzkhan str. 106, 744027

ASHHABAT, Turkmenistan -

View on map

YUNNAN HUAHANG ORAL APPLIANCE CO. LTD.

No. 302, Unit 1, Building 2, Xichang Road, Xishan District, 650000

Kunming, China -

View on map

Yong-Jia Dental Zhuhai

No. 10 Pingdongsanlu, 3rd floor, Room 301A, Nanping, 519000

ZHUHAI (GUANGDONG), China -

View on map

Zahntechnischer Service Inh. ZTM Matthias Michael Krause

Grünauer Straße 201-209, 12557

Berlin, Germany - View on map

- View on map

-

View on map

Zweithand Dental A. Pepping

Bertha-von-Suttner-Str. 7, 50259

Pulheim, Germany -

View on map

artsupport GmbH

Glattalstrasse 222, 8153

Rümlang, Switzerland -

View on map

austro dent GmbH

Goldschlagstraße 172/2, 1140

WIEN, Austria -

View on map

austro dent GmbH

Feldkirchner Straße 11-15, 8054

GRAZ, Austria - View on map

- View on map

-

View on map

austro dent GmbH

Helga-Krismer-Platz 1, 6020

INNSBRUCK, Austria -

View on map

cadflix GmbH

Salzburger Straße 77, 5500

BISCHOFSHOFEN, Austria -

View on map

feindent Inh. Mark Kallinich

Karl-Kellner-Str. 105K, 30853

Langenhagen, Germany -

View on map

iDent Slovakia, s.r.o.

Zelená str. 10617/7, 03608

MARTIN, Slovakia -

View on map

megadental GmbH

Seeweg 20, 63654

Büdingen, Germany -

View on map

van de Hoef & Renes B.V.

Oostergracht 42, 3763LZ

SOEST, Netherlands -

View on map

van der Ven Dental GmbH&Co.KG Dental Depot

An den Dieken 65, 40885

Ratingen, Germany - View on map

-

View on map

xWERK GmbH

Wettersteinring 17, 85221

Dachau, Germany -

View on map

Á-DENT Kft

Pacsirta U. 1, 6724

SZEGED, Hungary -

View on map

Čardakli d.o.o. Sarajevo

Tešanjska do broja 9, 71000

SARAJEVO, Bosnia and Herzegovina