The Subject of the Article

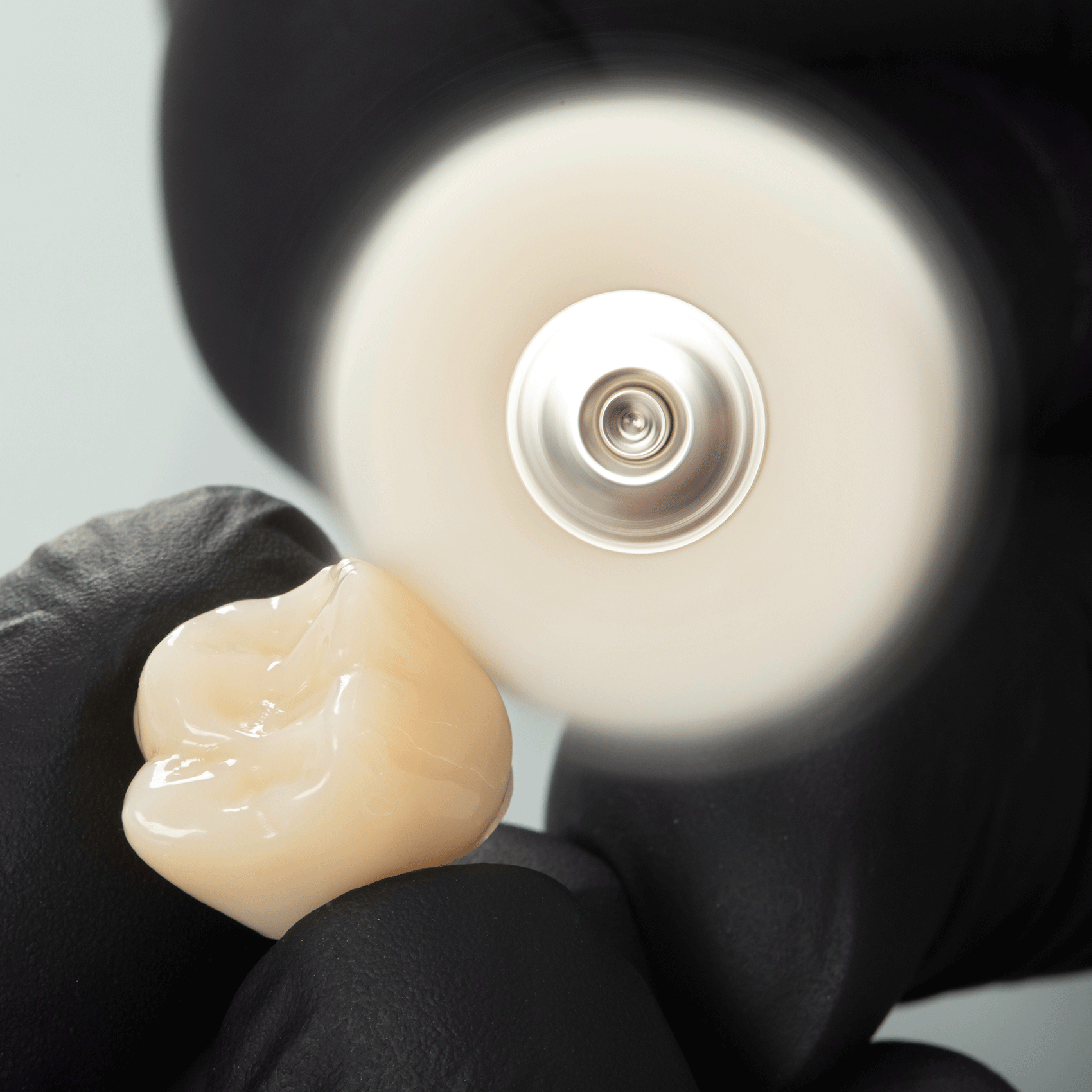

- Material-specific polishing is crucial for the long-term stability and esthetics of CAD/CAM restorations.

- Polished surfaces have been proven to reduce antagonist wear and plaque build-up.

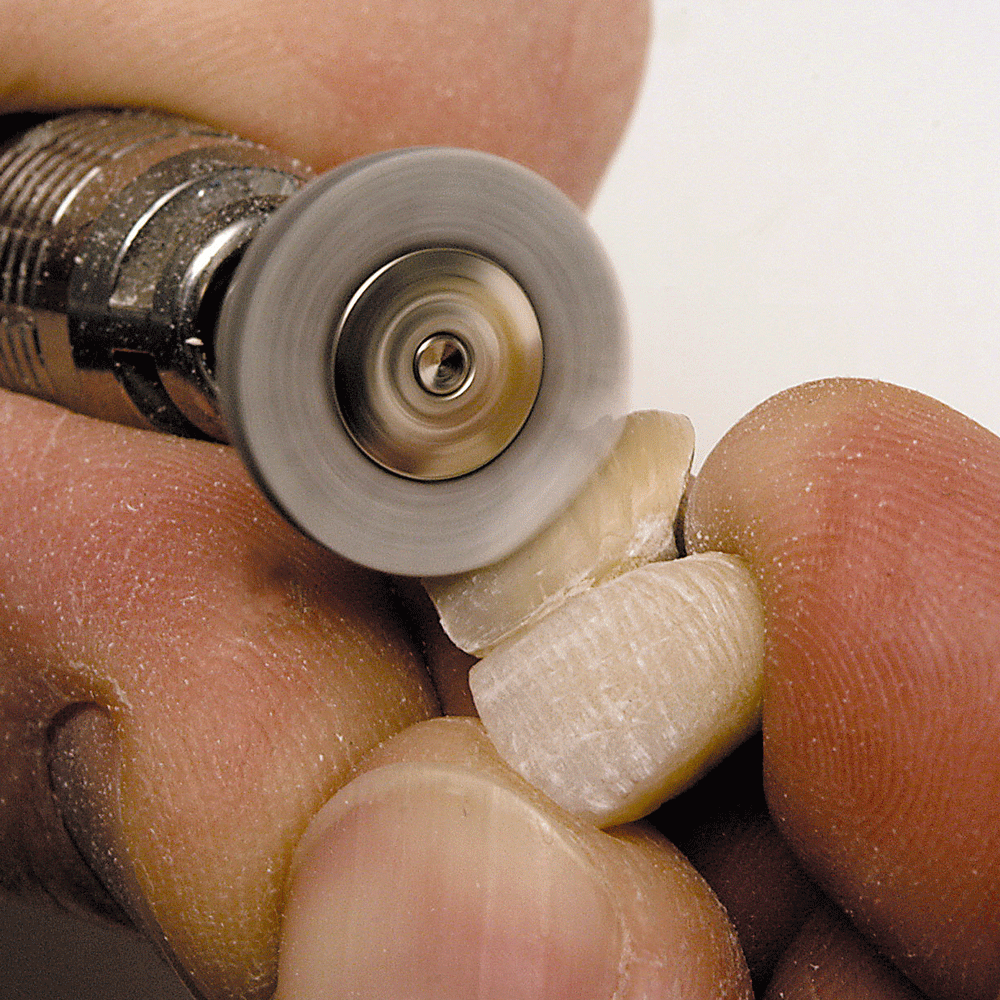

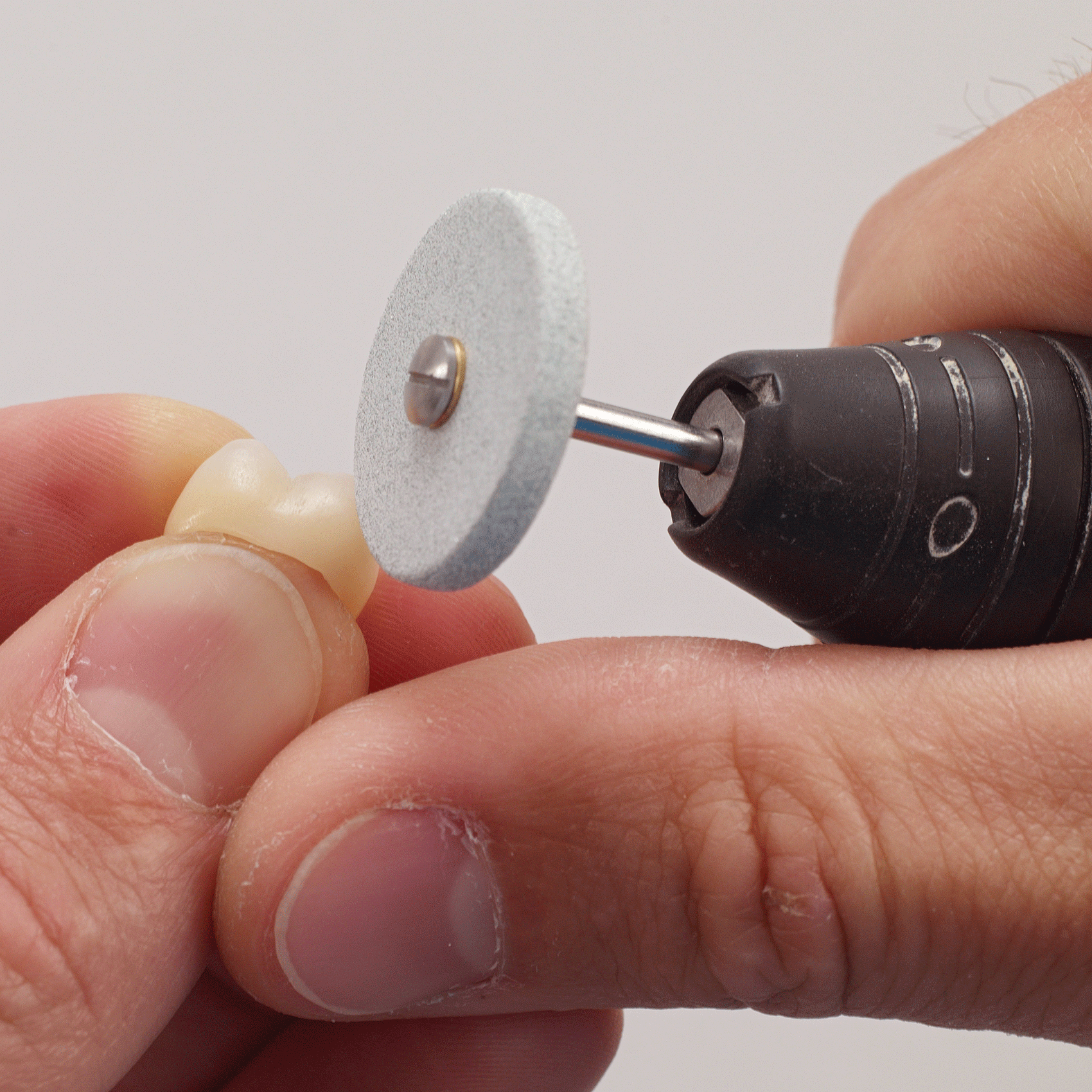

- Each material - zirconium oxide, lithium disilicate, hybrid materials - requires customized polishing protocols.

- Scientifically developed polishing systems achieve reproducible high luster results.

➤ In Part 2 of our polishing guide, you will learn more about the scientifically proven advantages of polishing CAD/CAM restorations